Yesterday, I wrote about fixing pixels. These are relatively straightforward and relatively easy to do in the course of the year. Besides the 10,200 pixels we have 4 LED panel displays (called matrixes). Two large ones (one P5 and one P10) and two smaller ones (one P5 and one P10). The number in the type of panel denotes the pixel resolution. P5 the individual SMD LED chips are 5 mm apart from one another while P10 they are 10 mm apart. These chips are SMALL – and as I use indoor panels in an enclosure, though the weather does not effect them the temperature does.

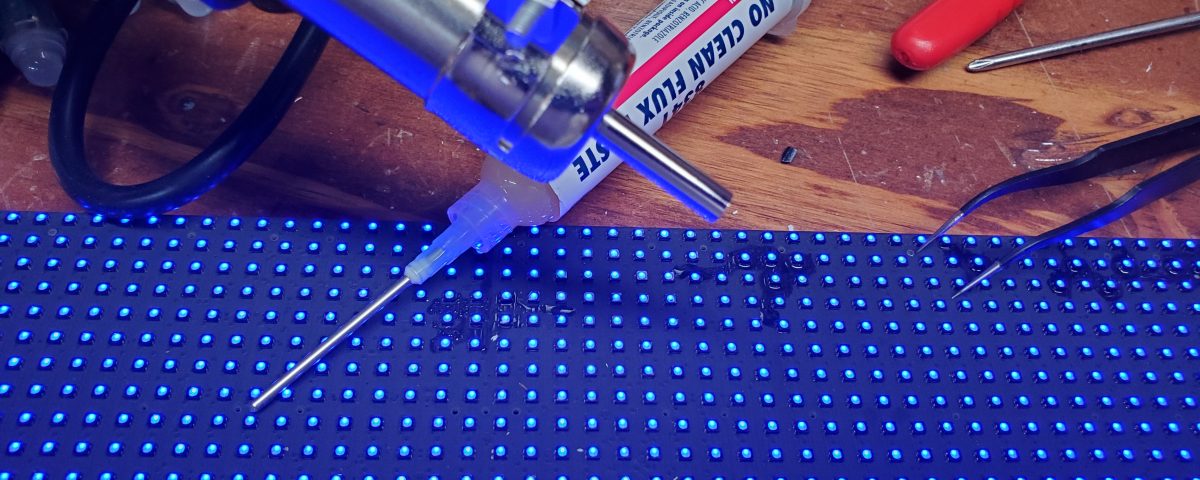

During this past off season, I ended up replacing several panels in my matrixes because they had LED’s that were not working. Recently, I decided take a look at fixing them. With the right tools – mainly soldering paste, a good pair of tweezers and a SMD reworking station (hot air soldering gun), fixing the panels is pretty straightforward.

As you can see in the video, once the panels are removed and the plastic cover taken off (there are nine tiny screws in each side of a P5 panel that keeps a plastic cover in place over the LED’s), fixing them is fairly easy. Just applying a little soldering paste to the two side of the SMD LED and heating at 300° C the chips most of the time slip back into place. Some require a little maneuvering with pliers, but for the most part they are pretty easy to fix.